With a dynamite blast at a quarry launches, the ground trembles, and the air fills with the deafening roar of an explosion. This destructive force, harnessed for the extraction of valuable materials, comes with inherent risks and environmental consequences. Embark on a journey to understand the dynamics, impacts, and safety protocols surrounding dynamite blasts in quarries, unraveling the complexities of this hazardous yet essential industry.

From the initial detonation to the long-term repercussions, this comprehensive analysis delves into the causes, consequences, and mitigation measures associated with quarry blasts. We will explore the role of safety regulations, trained personnel, and technological advancements in minimizing the risks posed by these powerful explosions.

Event Description

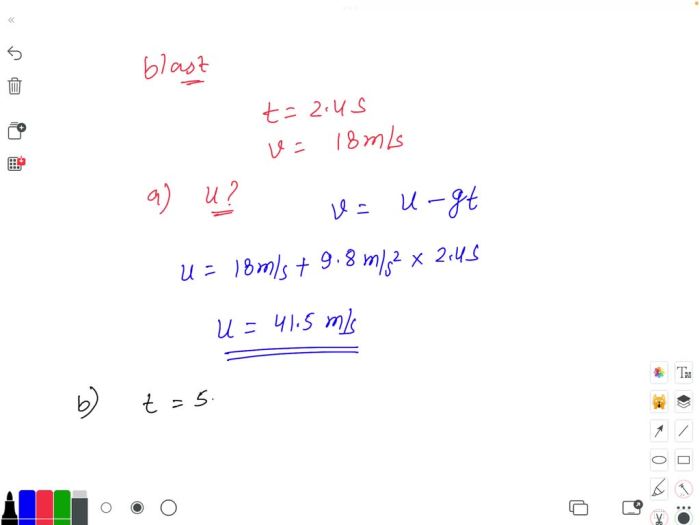

A dynamite blast at a quarry involves the controlled detonation of explosives to extract or shape rock materials. The sequence of events leading to the blast typically includes:

- Drilling and Blasting Plan:Geologists and engineers carefully design a plan for drilling holes into the rock, determining the placement and amount of explosives to be used.

- Hole Drilling:Specialized drilling equipment is used to create holes of the desired depth and diameter at precise locations within the rock.

- Explosive Loading:Dynamite cartridges or other explosives are carefully loaded into the drilled holes, ensuring proper spacing and orientation.

- Tamping:Inert material, such as sand or gravel, is used to fill the remaining space in the holes, creating a tight seal to maximize the explosive force.

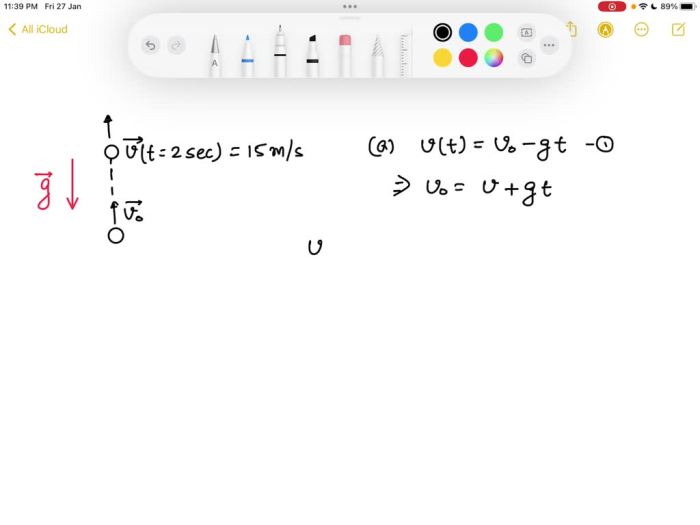

- Detonation:The explosives are detonated using a controlled electrical or non-electrical initiation system, causing a rapid release of energy and creating a shockwave.

Potential Causes of the Blast

Potential causes of a dynamite blast at a quarry can include:

- Improper Drilling and Blasting Plan:Errors in the design or execution of the drilling and blasting plan can lead to unexpected results.

- Inadequate Explosive Loading:Insufficient or improper loading of explosives can result in incomplete rock breakage or unintended consequences.

- Faulty Initiation System:Malfunctions or errors in the initiation system can cause premature or delayed detonation.

- Unstable Rock Conditions:Unexpected geological conditions, such as fissures or water seepage, can affect the stability of the rock and increase the risk of uncontrolled blasting.

- Human Error:Mistakes or negligence during any stage of the blasting process can contribute to accidents.

Impact Assessment

The detonation of explosives in a quarry blast has both immediate and long-term environmental impacts. Understanding these impacts is crucial for developing appropriate mitigation strategies and ensuring the safety of nearby communities and infrastructure.

Immediate impacts include ground vibrations, airblast, and flyrock. Ground vibrations can cause damage to structures, while airblast can shatter windows and cause hearing loss. Flyrock, or fragments of rock ejected from the blast, poses a safety hazard to workers and nearby residents.

Long-Term Impacts

- Noise pollution:Ongoing blasting operations can generate significant noise, affecting the quality of life for nearby communities.

- Dust generation:Blasting and excavation activities produce large amounts of dust, which can contribute to air pollution and respiratory issues.

- Water contamination:Explosives and rock fragments can enter nearby water bodies, potentially contaminating drinking water sources and harming aquatic ecosystems.

- Habitat fragmentation:Quarrying operations can fragment natural habitats, disrupting wildlife and reducing biodiversity.

Mitigation Measures

To mitigate these impacts, quarries implement various measures, including:

- Controlled blasting techniques:Using precise timing and placement of explosives to minimize ground vibrations and airblast.

- Flyrock control measures:Installing blast mats and barriers to contain rock fragments.

- Noise barriers:Constructing walls or berms to absorb or deflect noise.

- Dust suppression systems:Using water sprays or chemical suppressants to reduce dust emissions.

- Water monitoring and treatment:Regularly monitoring water quality and implementing treatment systems to prevent contamination.

- Habitat restoration:Reclaiming and restoring quarry sites to create new habitats for wildlife.

Safety Procedures

Quarry blasts involve the controlled use of explosives to fragment rock, and ensuring safety during these operations is paramount. Strict protocols and regulations govern the conduct of quarry blasts to minimize risks to personnel, the environment, and surrounding communities.

Trained personnel are crucial for safe blasting operations. They undergo rigorous training to acquire the knowledge and skills necessary to handle explosives safely and effectively. They are responsible for planning, preparing, and executing blasts according to established safety standards.

Specialized Equipment, A dynamite blast at a quarry launches

Specialized equipment plays a vital role in enhancing safety during quarry blasts. This equipment includes:

- Detonators:Electric or non-electric detonators initiate the explosion, and their proper selection and use are critical for precise timing and control.

- Blasting machines:These devices provide the electrical current necessary to trigger the detonators, ensuring safe and reliable initiation.

- Blast mats:Heavy-duty mats placed over the blast area contain flying debris, minimizing the risk of damage to personnel and equipment.

- Seismographs:These instruments monitor ground vibrations caused by the blast, ensuring compliance with vibration limits and preventing potential damage to nearby structures.

Planning and Risk Assessment

Thorough planning and risk assessment are essential for safe quarry blasts. This involves:

- Site selection:Careful consideration of the location, geology, and proximity to sensitive areas is necessary to minimize risks.

- Blast design:Engineers design the blast pattern, charge weight, and timing to optimize fragmentation while controlling vibration and airblast.

- Environmental impact assessment:Potential impacts on air quality, noise, and water resources are assessed and mitigation measures are implemented.

- Emergency response plan:A comprehensive plan Artikels procedures for handling potential emergencies, including medical emergencies, fires, and unexploded charges.

By adhering to established safety protocols, utilizing specialized equipment, and conducting thorough planning and risk assessment, quarry blasts can be conducted safely and effectively, minimizing risks to personnel, the environment, and surrounding communities.

Industry Practices: A Dynamite Blast At A Quarry Launches

Quarry blasting techniques vary widely across the industry, influenced by factors such as rock properties, quarry geometry, and environmental constraints. Comparative analysis reveals distinct approaches tailored to specific contexts.

The choice of blasting method hinges on several factors, including rock strength, fracture characteristics, desired fragmentation size, and proximity to sensitive areas. Each method presents unique advantages and limitations, necessitating careful consideration for optimal results.

Technological Advancements

Technological advancements have revolutionized quarry blasting, enhancing efficiency, precision, and safety. Electronic detonators, for instance, enable precise timing and sequencing of explosions, optimizing fragmentation and minimizing environmental impact.

Computer modeling and simulation tools play a crucial role in blast design, allowing engineers to predict blast effects and optimize parameters for specific quarry conditions. This technology facilitates informed decision-making and reduces the risk of adverse outcomes.

Remote monitoring systems enhance safety by allowing operators to monitor blast operations from a safe distance. These systems provide real-time data on blast parameters, enabling timely interventions and minimizing potential hazards.

Automated drilling and blasting equipment further enhances efficiency and reduces labor requirements. These machines operate with high precision, ensuring consistent hole patterns and precise explosive placement.

Case Studies

Notable dynamite blasts at quarries have occurred throughout history, providing valuable insights into the causes, consequences, and lessons learned from these incidents. These case studies offer crucial information for refining blasting practices and enhancing safety measures in the quarrying industry.

Blast at a Quarry in West Virginia, USA

In 2019, a dynamite blast at a quarry in West Virginia resulted in the release of approximately 1,200 pounds of ammonium nitrate into the surrounding environment. The blast occurred during the preparation of a new blasting area, and an investigation revealed that the detonation had caused a crack in a storage tank containing the ammonium nitrate.

The incident highlighted the importance of proper storage and handling of explosives, as well as the need for effective emergency response plans to mitigate potential environmental impacts.

Blast at a Quarry in France

A blast at a quarry in France in 2018 resulted in the death of one worker and injuries to two others. The incident occurred during the detonation of a large charge of dynamite, and an investigation revealed that the blast had caused a rockfall that struck the workers.

The case study emphasized the critical role of proper planning, risk assessment, and adherence to safety protocols to prevent accidents during blasting operations.

Blast at a Quarry in Australia

A blast at a quarry in Australia in 2016 resulted in significant damage to a nearby residential area. The blast occurred during the detonation of a series of charges, and an investigation revealed that the charges had been improperly placed, resulting in an uncontrolled explosion that sent debris flying into the surrounding community.

The incident underscored the importance of careful planning and execution of blasting operations to minimize the risk of damage to property and infrastructure.

Lessons Learned from Case Studies

These case studies provide valuable lessons for the quarrying industry, including:

- The importance of proper storage and handling of explosives

- The need for effective emergency response plans to mitigate potential environmental impacts

- The critical role of proper planning, risk assessment, and adherence to safety protocols to prevent accidents

- The importance of careful planning and execution of blasting operations to minimize the risk of damage to property and infrastructure

By incorporating these lessons into blasting practices, the quarrying industry can enhance safety, reduce environmental risks, and minimize the potential for incidents.

FAQ Summary

What are the primary causes of dynamite blasts at quarries?

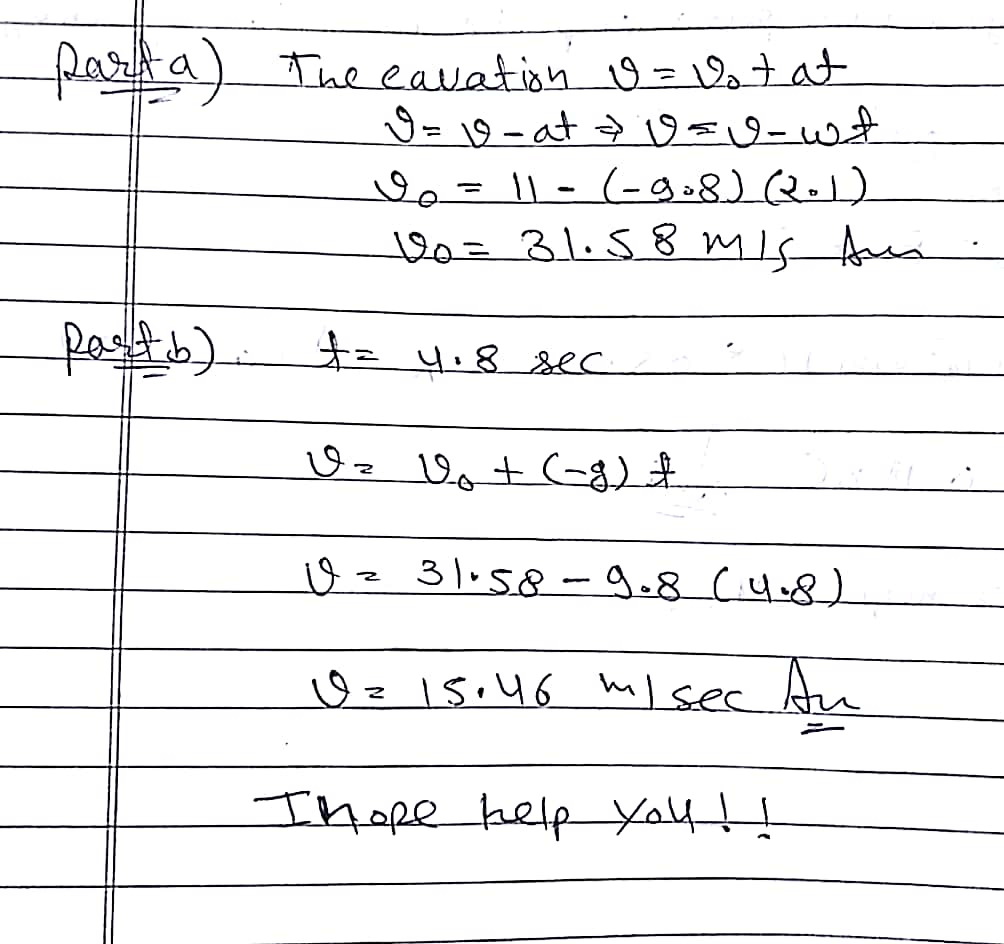

The detonation of dynamite in quarries is typically caused by human error, equipment malfunctions, or unforeseen geological conditions.

What are the immediate environmental impacts of a dynamite blast?

Quarry blasts can release harmful pollutants into the air and water, damage surrounding vegetation, and disrupt wildlife habitats.

How are safety protocols enforced during quarry blasts?

Rigorous safety protocols involve trained personnel, specialized equipment, proper planning, and risk assessments to minimize the hazards associated with blasting operations.